Introduction

In the intricate world of internal combustion engines, the rocker arm plays a pivotal role in ensuring efficient valve operation. Acting as a lever, it transmits the camshaft’s motion to the engine’s valves, facilitating their opening and closing. This function is crucial because the timing and precision of valve movements directly influence engine performance and efficiency. Without the rocker arm’s reliable operation, the entire combustion process could be compromised, leading to decreased power output and increased emissions.

Moreover, rocker arms come in various designs and configurations, each tailored to meet specific performance needs and engine designs. From traditional stamped steel rocker arms to more advanced roller rockers, the choice of rocker arm can significantly affect the engine’s responsiveness and overall efficiency. Understanding the types and functions of rocker arms is essential for anyone keen on engine mechanics or automotive engineering, as it provides valuable insights into how different components work together to optimize performance. By delving deeper into the mechanics of rocker arms, enthusiasts and professionals alike can appreciate the complexities of engine design and the innovations that drive the automotive industry forward.

What is a Rocker Arm?

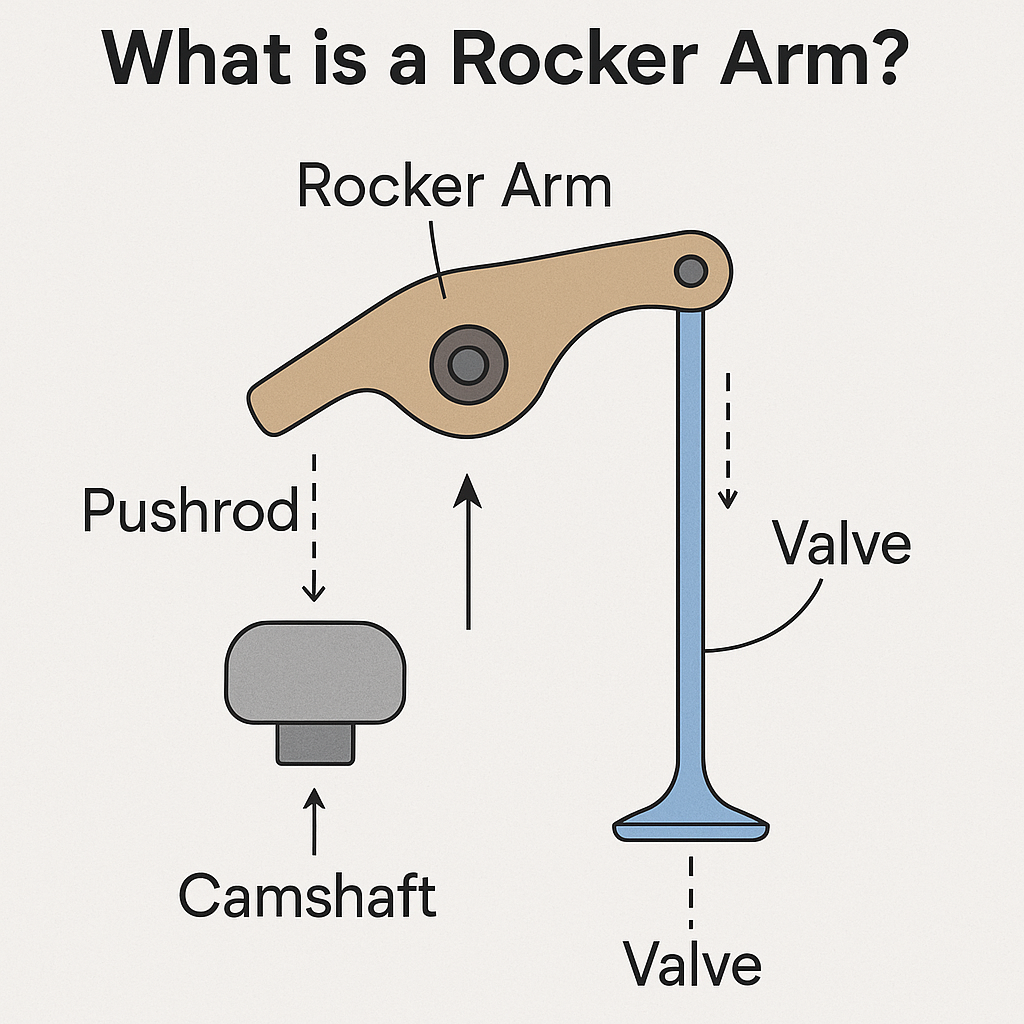

A rocker arm is a crucial component in the valve train of an internal combustion engine. It serves as a bridge between the camshaft and the engine valves, playing a pivotal role in the engine’s overall performance. When the camshaft rotates, its lobes push against the rocker arm, causing it to pivot and press down on the valve stem, thereby opening the valve. This action is essential for allowing the air-fuel mixture to enter the combustion chamber or for exhaust gases to exit after combustion.

As the cam lobe rotates further, the pressure on the rocker arm is released, and the valve closes, ensuring that the timing of the engine’s intake and exhaust cycles is accurately maintained. This opening and closing of the valves must occur at precise intervals to optimize engine efficiency and power output. Moreover, the design and materials used in rocker arms can significantly influence an engine’s performance, durability, and responsiveness.

Functions of Rocker Arms

-

Valve Operation: The primary function is to open and close the engine’s intake and exhaust valves in sync with the piston movement.

-

Motion Transfer: It translates the rotational motion of the camshaft into linear motion to operate the valves

-

Force Amplification: Rocker arms can amplify the camshaft’s motion, allowing for greater valve lift without altering the camshaft design

-

Friction Reduction: Advanced designs, like roller rocker arms, minimize friction between components, enhancing efficiency and reducing wear.

-

Durability: Modern rocker arms are designed to withstand high stresses and temperatures, ensuring longevity and consistent performance.

Types of Rocker Arms

1. Stamped Steel Rocker Arms

These are the most common and cost-effective rocker arms, typically found in standard production vehicles. Made by stamping steel sheets, they are lightweight but may lack the strength required for high-performance applications.

2. Roller Rocker Arms

Equipped with a roller at the contact point, these rocker arms reduce friction and wear. They are ideal for high-performance engines where efficiency and durability are paramount.

3. Full Roller Rocker Arms

These have rollers at both the valve and pushrod ends, offering maximum friction reduction. Commonly used in racing engines, they provide enhanced performance and longevity.

4. Shaft Rocker Arms

Instead of individual pivot points, these rocker arms are mounted on a shaft, providing increased stability and uniform motion. They are often found in high-performance and racing engines.

5. Aluminum Rocker Arms

Lightweight and corrosion-resistant, aluminum rocker arms are suitable for high-revving engines. However, they may wear faster than steel counterparts under extreme conditions.

6. Steel Rocker Arms

Known for their strength and durability, steel rocker arms are heavier but can withstand higher stresses, making them suitable for heavy-duty applications.

Importance of Rocker Arm Ratio

The rocker arm ratio is the relationship between the camshaft’s lift and the valve’s lift. For instance, a 1.5:1 ratio means the valve lifts 1.5 times the camshaft’s lift. This relationship is crucial because it directly affects how efficiently the engine breathes, which in turn impacts overall performance. Adjusting this ratio can influence engine performance, affecting factors like horsepower and torque.

Moreover, a higher rocker arm ratio can allow for a more significant valve lift, which may enhance airflow into and out of the combustion chamber. This increased airflow can lead to improved combustion efficiency, thereby generating more power. Conversely, a lower rocker arm ratio might result in reduced lift, limiting the engine’s ability to produce maximum power, but it can also provide smoother operation and better drivability at lower RPMs.

Common Issues with Rocker Arms

-

Wear and Tear: Over time, rocker arms can wear out, leading to inefficient valve operation.

-

Noise: A ticking or tapping noise from the engine may indicate a faulty rocker arm.

-

Performance Loss: Damaged rocker arms can lead to reduced engine performance and fuel efficiency.

-

Valve Damage: Faulty rocker arms can cause improper valve timing, potentially damaging the valves and other engine components.

Maintenance Tips

-

Regular Inspection: Periodically check rocker arms for signs of wear or damage.

-

Proper Lubrication: Ensure adequate lubrication to minimize friction and wear.

-

Timely Replacement: Replace worn or damaged rocker arms promptly to prevent further engine issues.

-

Use Quality Parts: Opt for high-quality rocker arms suitable for your engine’s specifications and performance requirements.

Conclusion

Rocker arms are integral to the efficient operation of internal combustion engines. These mechanical components play a crucial role in converting the linear motion of the engine’s camshaft into the rotational motion needed to open and close the engine’s valves. Understanding their types and functions can aid in better maintenance and performance optimization. For instance, different types of rocker arms, such as stamped, roller, and adjustable rocker arms, each offer unique benefits that can significantly impact engine performance.

Whether you’re a car enthusiast or a professional mechanic, knowledge about rocker arms is invaluable in ensuring engine longevity and efficiency. By familiarizing yourself with the various designs and their specific applications, you can make informed decisions when it comes to upgrades or repairs, ultimately enhancing your vehicle’s overall performance and reliability. Furthermore, recognizing the signs of rocker arm wear or failure can help prevent more extensive damage to the engine, saving both time and money in the long run.